Key updates on metallurgical standards, including graphene oxide analysis, high-strength steel, alloys, and advanced testing methods, effective May 2025.

Метод очистки AOD является аббревиатурой аргонно-кислородного обезуглероживания (Argon Oxygen Decarburization), при очистке нержавеющей стали путем снижения парциального давления CO, для достижения эффекта ложного вакуума, чтобы снизить содержание углерода до очень низкого уровня и подавить окисление хрома в стали. Принцип обезуглероживания кислородной продувкой AOD заключается в том, что кислород, вдуваемый в…

Застежки, подшипники, шестерни, пружины, плесени и умирают, являются основными частями механического производства, которые напрямую влияют на качество и надежность машин. Застежки, подшипники, шестерни, пружины, плесени и другую среду обслуживания различны, качество требований к материалам также различено. Крепежные стали Застежки являются крупнейшим применением основных деталей, крепежных изделий со стальными крышками практически…

Технологии энергосбережения и снижения выбросов углерода в металлургической промышленности Технология прямого восстановления отработанного тепла высокотемпературного твердого сыпучего материала использует интегрированное устройство охлаждения твердого сыпучего материала и рекуперации отработанного тепла, которое напрямую восстанавливает явное тепло высокотемпературного твердого сыпучего материала без введения промежуточной газовой теплоносителя. Высокотемпературные твердые частицы используют собственную гравитацию, чтобы…

Answer: Fine material principle to reduce the amount of slag. Reasonable slagging system. Reasonable oxygen supply system, loading system to reduce mechanical spattering. Thermal compensation technology, consume more scrap to reduce chemical burn loss. Reasonable re-blowing technology.

Stainless steel has high deformation resistance, generally twice that of ordinary carbon steel. During cold working, deformed martensite forms, causing a rapid work hardening rate and requiring greater rolling force and load. Requirements Stainless Steel Cold Rolling Mill Should Meet Work rolls should be of small diameter as much as…

Roll flaw detection is essential for almost all high-standard rolling mill. Common methods for roll flaw detection include magnetic particle flaw detection, penetrant color flaw detection, eddy current flaw detection, and ultrasonic flaw detection. Magnetic Particle Flaw Detection: This technology is primarily used to identify surface cracks on the roll body…

New-product: 1100MPa High-strength Solid Wire At present, there isn’t a matching welding material with the1100MPa high-strength steel plate, most of the industry is forced to use 900MPa grade wire, in the design to avoid the welding joint force, which brings more trouble to the equipment design, but also is the…

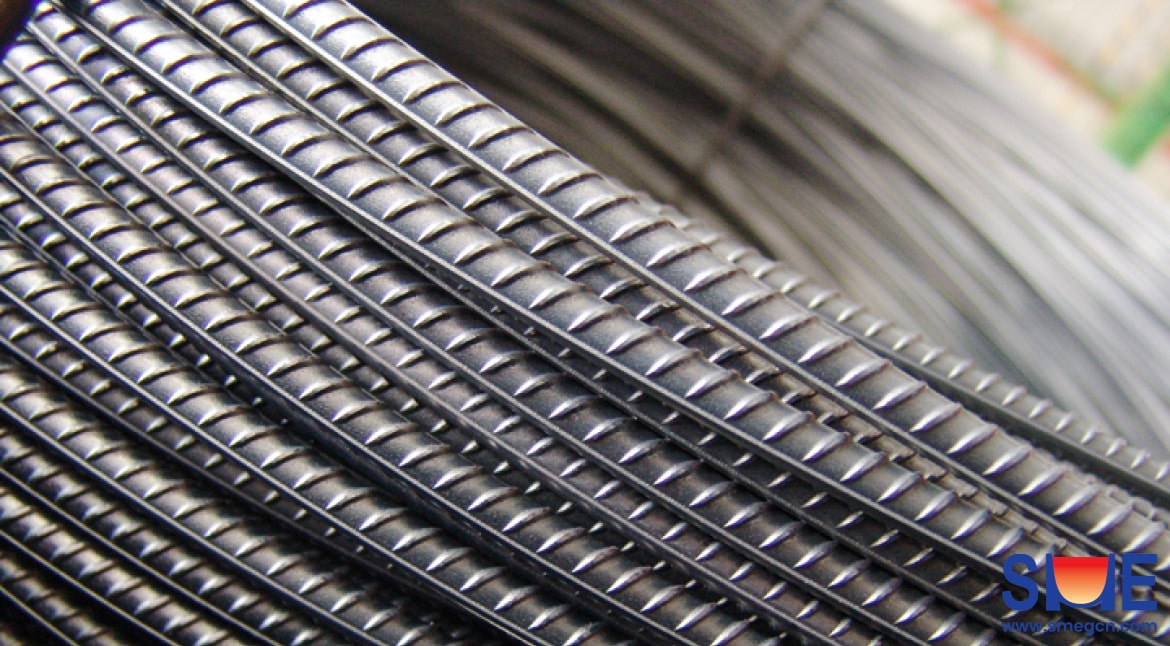

New or expanded bars or wire rod production line is mostly used in H/V arrangement of short-stress rolling mill, it is compared with the traditional mill, this compact rolling line reduces the weight of equipment and plant construction costs. The characteristics of the short stress rolling mill: The rigidity of the mill is good, and the dimensional…

The rolls of hot rolling mill or cold cooling mill act key role in the rolling process. The shape (convexity, concavity, taper,etc) of the roll can impact the quality of final products. In the rolling process along the length of the roll, the distance between the upper and lower rolls should…