Plants

Get Your Tailored

Solution Now!

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Direct reduction iron or direct reduced iron, is widely considered a sustainable route for ironmaking. Shanghai Metallurgy Equipment Group, SME Group, as a trusted EPC (Engineering, Procurement, and Construction) partner, we specialize in delivering tailored one-stop solution for iron plants. From design and construction to production management, SME handles everything and ensures your plant runs smoothly.

Major Equipment of DRI Plant

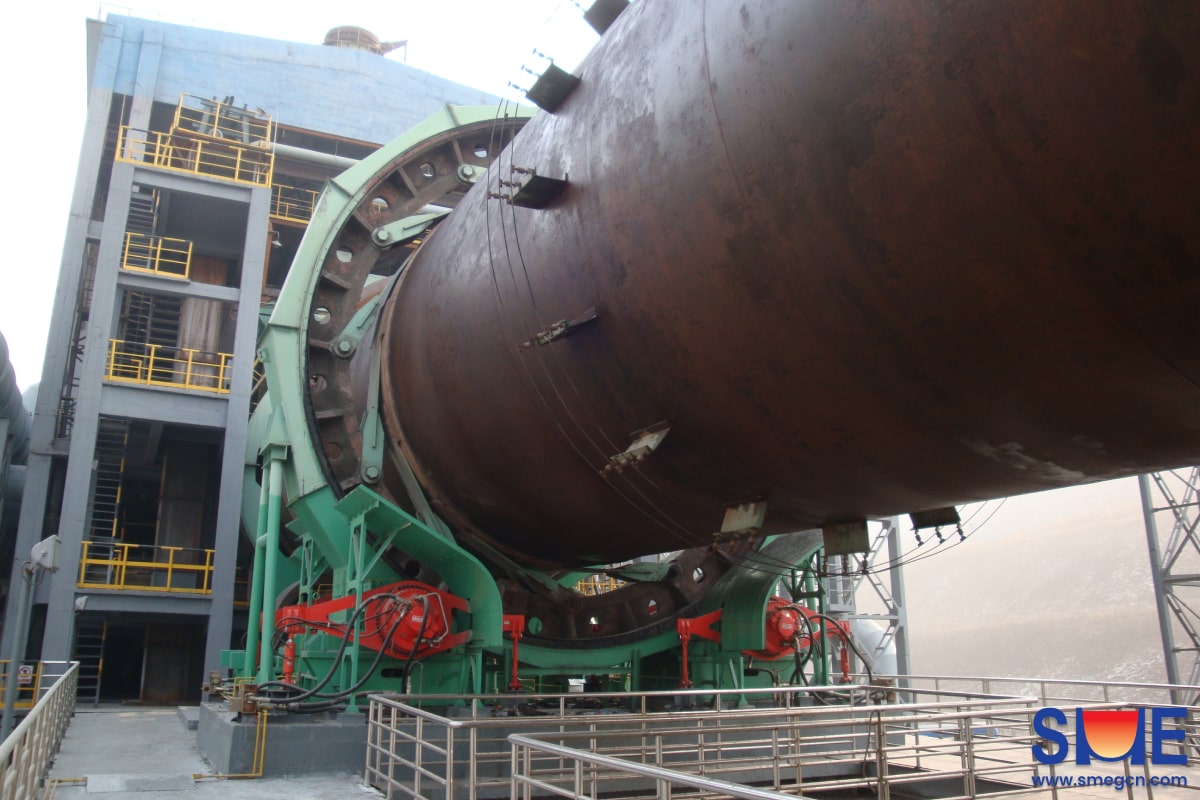

- Rotary Kiln: This ironmaking method uses a continuously rotating rotary kiln as a reactor and solid carbon as a reducing agent to reduce iron ore powder to metallic iron through solid-phase reduction reaction.

- Shaft Furnace:It is one direct reduction ironmaking method, which uses solid reducing agent to reduce iron ore through external heating.

The DRI Production Process

Our DRI plants are designed to optimize each step of the production process:

- Raw Material Preparation

- Drying and Crushing

- Automatic Charging

- Reduction Roasting

- Automatic Discharging and Products Treatment

Why Choose DRI for Iron Production?

The Direct Reduction Iron (DRI) process is a modern and efficient method for producing iron from iron ore. It stands out for several reasons:

- Energy Efficiency: DRI plants consume less energy compared to traditional blast furnaces, making them a more sustainable choice for iron production.

- Environmental Friendliness: With lower CO2 emissions, DRI production is a greener alternative, aligning with global efforts to reduce carbon footprints.

- Flexibility: DRI plants need not be part of an integrated steel plant, as is characteristic of blast furnaces.

- Lower requirements for raw materials: DRI plants are more suitable for developing countries where supplies of high grade coking coal are limited, but where steel scrap is generally available for recycling.

- Lower Cost: The initial capital investment and operating costs of direct reduction plants are lower than integrated steel plants.

- Quality of Product: The DRI produced is of high quality, suitable for a range of applications, including Electric Arc Furnace (EAF) steelmaking and foundry operations.