Stay updated with the July 2024 metallurgical standards, featuring advancements in alloys, steel production, seamless tubes, and rare earth steel applications.

Key updates on metallurgical standards, including graphene oxide analysis, high-strength steel, alloys, and advanced testing methods, effective May 2025.

The World Steel Association (WSA) has released the latest edition (2024-2025) of its Steel Demand Forecast Report (SRO). The report shows that global steel demand will fall by a further 0.9% to 1,751 million tons this year. After three consecutive years of decline, global steel demand will rebound by 1.2%…

2024 stainless steel industry operating conditions are manifested in the stainless crude volume, apparent consumption, import and export volume year-on-year growth. The price trend in the domestic market is low, export volume keeps increasing but the export price is low. The overall efficiency of the industry is low, and the…

The 2024 Metallurgical Science and Technology Award Grand Prize was awarded to Shougang Jingtang’s MCCR Multi-mode Continuous Casting and Rolling Technology Integration and Innovation project. The casting and rolling integration technology is a major advancement in the technology of the interface of the iron and steel manufacturing process. Mr. Wang Guolian,…

AOD refining method is the abbreviation of Argon Oxygen Decarburization (Argon Oxygen Decarburization), in refining stainless steel, by reducing the partial pressure of CO, to achieve the effect of false vacuum, so as to make the carbon content down to a very low level, and inhibit the oxidation of chromium…

SME will be participating in the upcoming GIFA MEXICO EXPO 2024 next month, from Qct.16 to Qct.18. This prestigious event offers us a unique opportunity to showcase our latest innovations and engage with industry leaders from around the world. SME team will be available to discuss your needs and share…

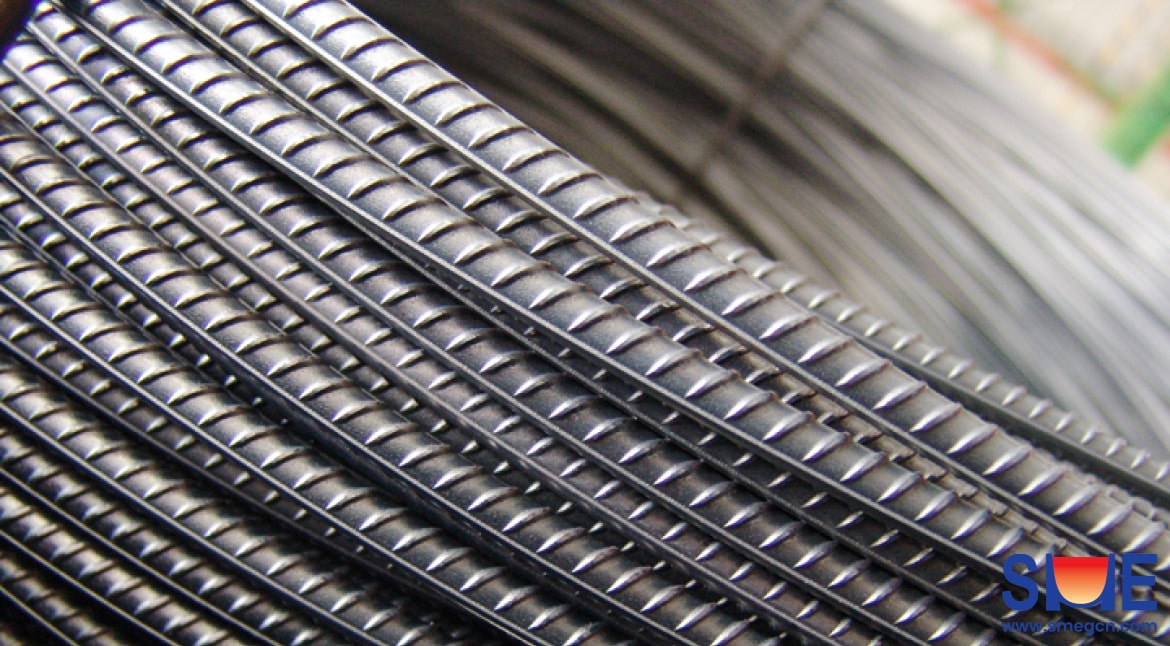

Fasteners, bearings, gears, springs, molds and dies are the basic parts of mechanical manufacturing, which directly affect the quality and reliability of machinery. Fasteners, bearings, gears, springs, molds and other service environment is different, the quality of the material requirements are also different. Fasteners steel Fasteners is the largest application…

Global crude steel production in August 2024 Global crude steel production in August 2024 in the 71 countries included in the World Steel Association statistics was 144.8 million tons, down 6.5% year-on-year. Crude Steel Production by Region In August 2024, Crude steel production in Africa was 1.9 million tons, down…

Energy Saving and Carbon Reduction Technologies in Iron and Steel Industry Waste heat direct recovery technology of High-temperature solid bulk material adopts the integrated device of solid bulk material cooling and waste heat recovery, which directly recovers the sensible heat of high-temperature solid bulk material without the introduction of intermediate gas…