Plants

Get Your

Solution Now!

Please feel free to contact us. We will get back to you with 1-2 business days.

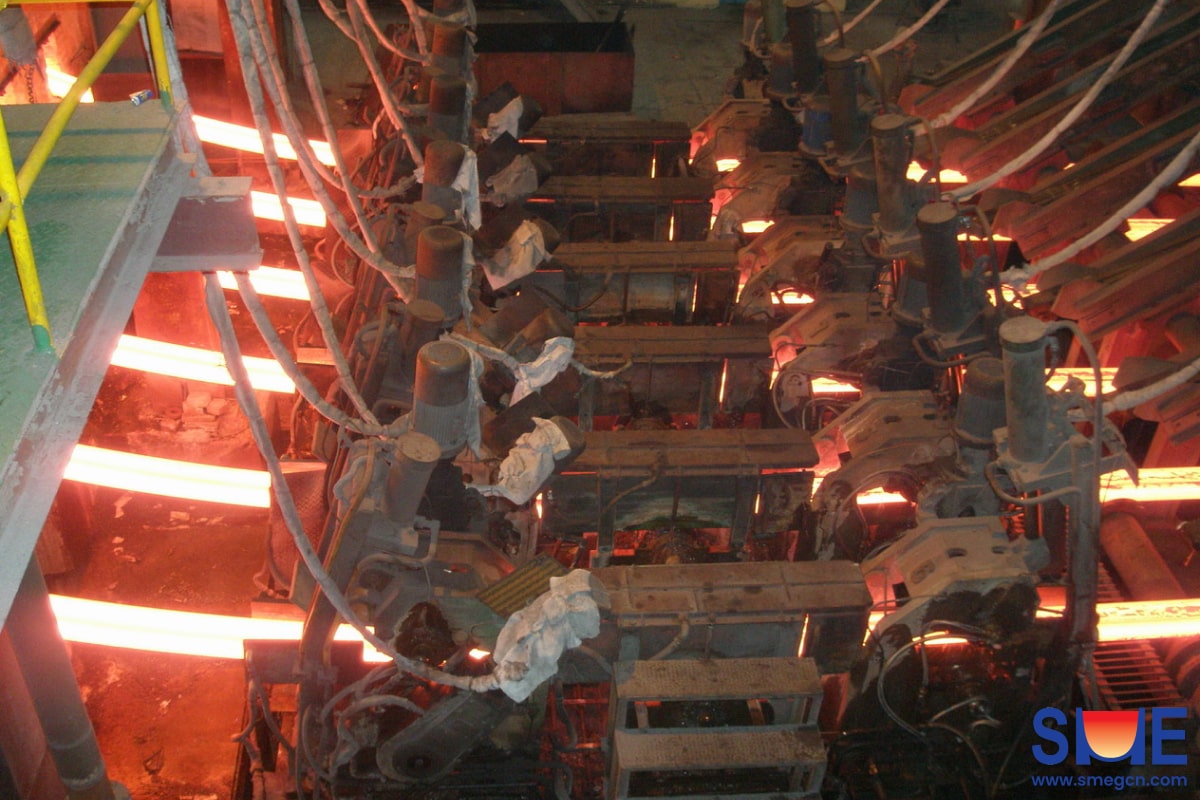

Shanghai Metallurgical Equipment Group specializes in turnkey/EPC steel projects. We provide total solutions for ironmaking, steelmaking and rolling mills. The continuous casting machine is a key equipment in the melt shop to produce semi-finished products such as billets and slabs. We customize the process configuration according to customer needs and build a smoothly running steelmaking plant from a greenfield site. SME Group’s engineers make full use of existing resources to install high-performance melt shops with excellent performance.

Key Components of Continuous Casting Machine (CCM)

- Ladle Turret

- Tundish

- Copper Mold with Level Control and Electromagnetic Stirrer

- Cooling Device

- Withdrawal and Straightening Machine

- Dummy Bar and Pinch Roll

- Cutting Machine: Hydraulic Shear or Flame Cutting

- Product Identification Device

- Convey System

Advantages of Our Continuous Casting Machine (CCM)

The advanced features and benefits of our CCM include:

- Process Simplification: Streamlines the billet production process, making it more straightforward and efficient.

- High Output Rate: Achieve higher metal yield and finished product rates.

- Energy Efficiency: Innovative engineering significantly reduces energy consumption.

- High-Quality Output: Precise process control ensures consistent and superior quality billets.

- Automation and Mechanization: Advanced automation minimizes manual intervention, boosting operational efficiency.

- Improved Working Conditions: Reduced labor intensity and enhanced safety for workers.

Get Free Quotation Now