Plants

Get Your Tailored

Solution Now!

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

As we all know, Induction Furnace steel-making has high requirements for scrap. Because metallurgical reactivity of Induction furnace is weak, its function is main to melt, thus it is necessary to select scrap according to the smelting steel type, and it is also impossible to smelt low carbon and low phosphorus and sulfur quality steel.

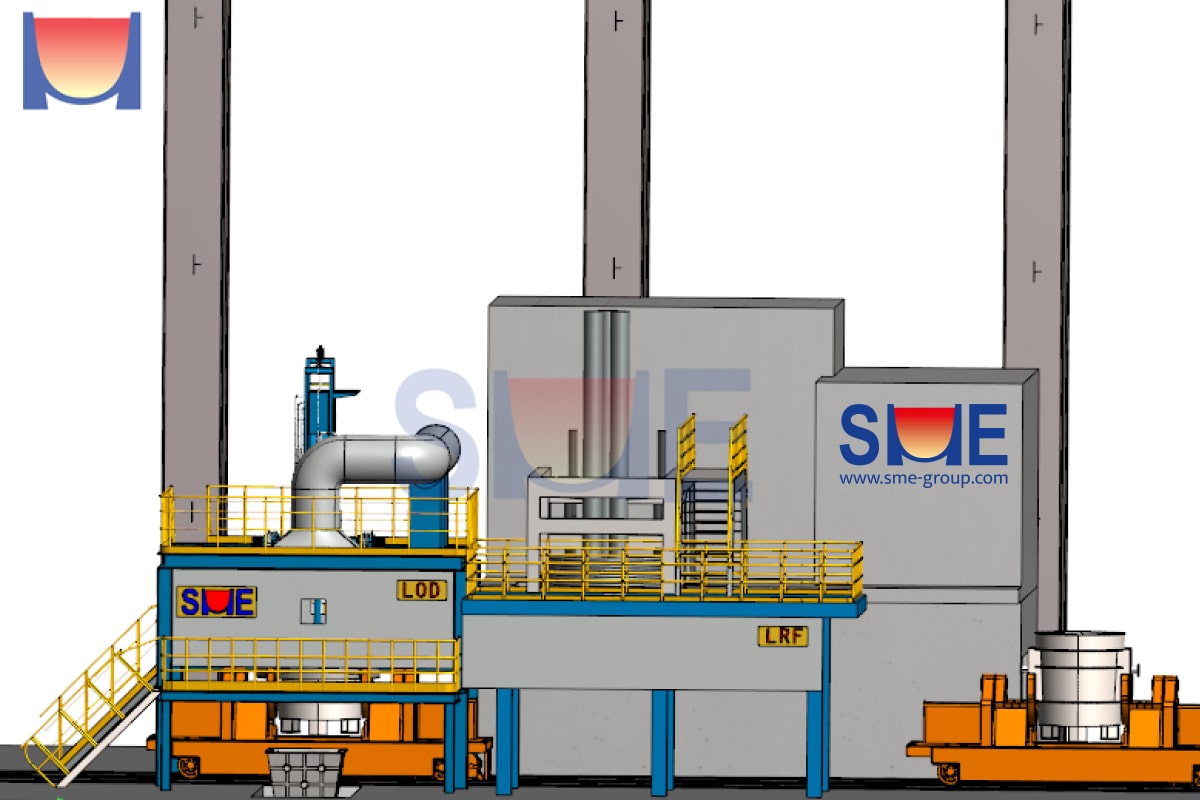

In response to these problems, SME has carried out research and development in-depth, retaining the advantages of low cost and easy operation of the induction furnace, and invented a new type of refining furnace – LOD furnace, matching with Ladle Furnace, the induction furnace can choose various kinds of scrap and smelt a variety of high quality alloy structural steel, high quality carbon steel and low carbon steel, basically reaching the production level of EAF+LF process. It can be said to be another revolution in the field of steel-making.

Highlights of IF+LOD+LRF process

- Compared with the EAF+LF process, it requires less investment, lower production cost, less auxiliary materials and equipment, and is simpler to operate.

- In the IF+LOD+LF process, the standard requirements for raw materials are very low, and iron lumps, high carbon scrap, ~20% pig iron, etc. can also be used as raw materials, which truly saves costs.

- The finished product is not restricted by the composition of scrap steel. The LOD process can not only produce steel billets/slabs for rebar, but for wire rods and narrow strip, which is very suitable for customers' market demand for multiple varieties of products.

- Easy upgrade: The existing induction furnace melt shop can be upgraded with only a small area required.

Get Free Quotation Now