Plants

Get Your

Solution Now!

Please feel free to contact us. We will get back to you with 1-2 business days.

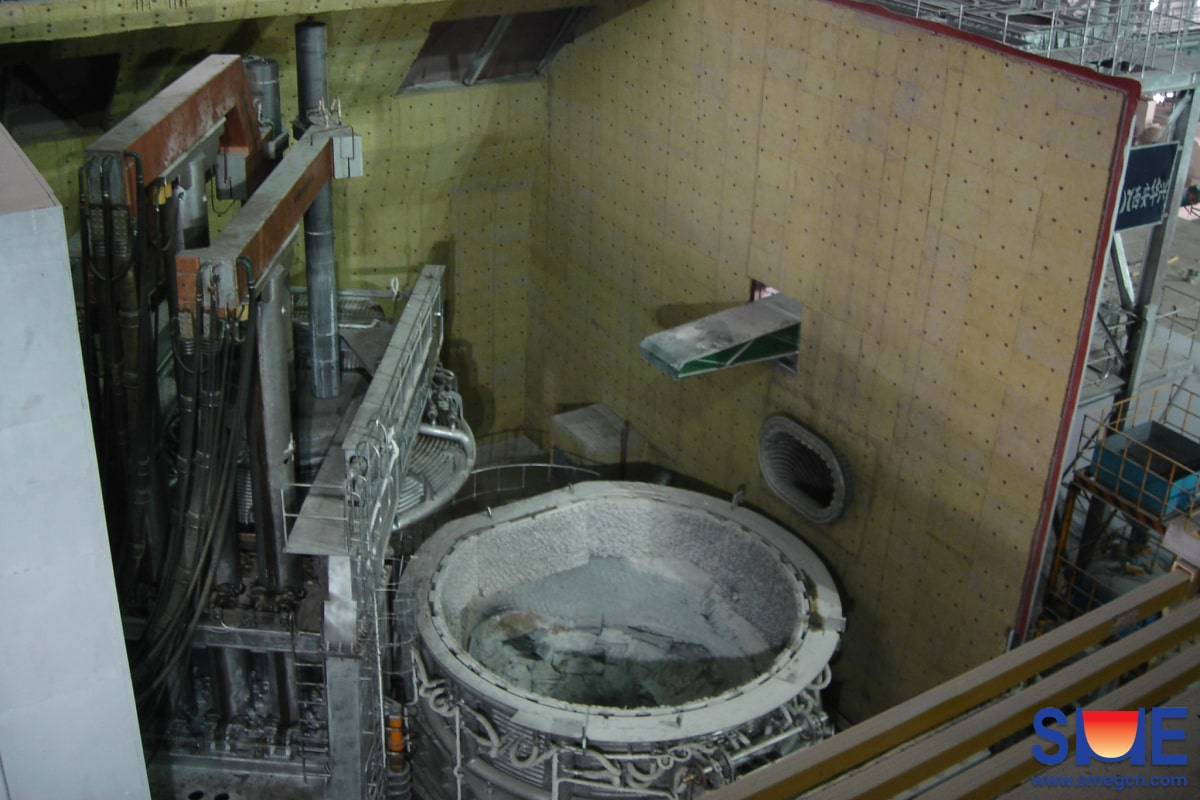

Shanghai Metallurgical Equipment Group (SME Group) is committed to providing one-stop solutions for the steel industry. One of our main products, Electric Arc Furnace (EAF), is a widely used steelmaking technology that features high efficiency, sustainability and high quality in steel production.

What is Electric Arc Furnace Steelmaking?

EAF, electric arc furnace, is usually grouped with LF, ladle furnace to produce low carbon steel. It may take scrap, iron ore DIY, alloys and etc. as input material. It is a kind of short-process steelmaking that can reduce carbon emission and widely considered eco-friendly. EAF is a mature and widely used technology in the modern steel industry.

Main Systems of Electric Arc Furnace Steelmaking

- Scrap Charging System

- Retractable Roof

- Graphite Electrodes

- Power Supply

- Oxygen Injection System

- Water Cooling Device

- Ladle and Tapping System

- Control and Automation System

Other Main Equipment in EAF Steelmaking

The EAF steelmaking process is equipped with equipment like:

- Ladle Refining Furnace (LRF): For further refining of the molten steel.

- Argon Oxygen Decarburization (AOD)

- Continuous Casting Machine (CCM): Transforms molten steel into solid billets or slabs as final products.

The Role of EAF in Steelmaking

The EAF plays a key role in the steelmaking process, offering a number of advantages:

Pros of EAF Steelmaking

- Sustainability: Less greenhouse gas emission.

- Flexibility: Capable of processing a wide range of inputs, including scrap, iron ore, direct reduced iron (DRI), and alloys.

- Quality: The EAF process is renowned for producing high-quality steel with precise chemical composition.

Cons of EAF Steelmaking

- High Impact on Power Grid: Not applicable for a number of projects due to power grid restriction.

- Complex operation: Compared with induction furnaces steelmaking, the operation is much more complicated and requires workers to have a higher level of knowledge.

- Cost: Initial investment and operational costs are much higher than induction furnace steelmaking.

EAF Plant Construction Service

SME Group has rich experience, offering the most cost-effective solutions and advanced technology services in EAF steelmaking engineering. Please check our successful cases in various countries around the world.

Our comprehensive service package includes:

- Plant Design: Tailored to meet your specific production needs.

- Construction and Erection: Expertise in building and assembling the steel plant infrastructure.

- Project Management: Comprehensive management from planning to execution, ensuring your project runs smoothly and on budget.

- Production Management: Optimize your operations and maximize output.

- Technical Service and Plant Operations: Ongoing support to ensure the smooth running of your facilities.

Get Free Quotation Now